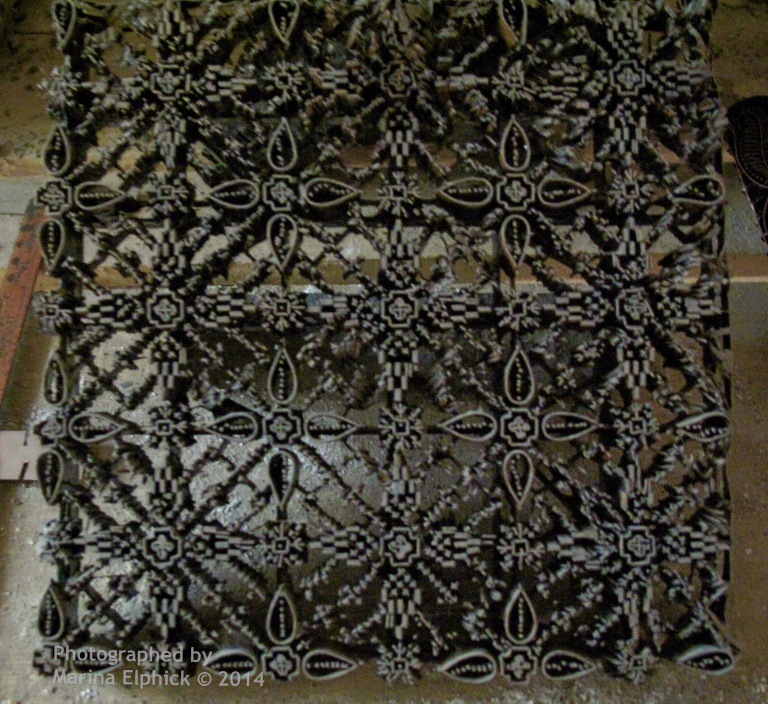

Batik cap is a batik method in which designs are applied in wax with cap stamps or ‘chaps’ as they are pronounced. They are usually made of copper for its heat conductive properties and used to ‘print’ hot wax on to cotton. Batik made like this has been produced in Java since the middle of the 19th century to speed up the production and lower the cost of batik cloth.

Producing batik cap is still a labour intensive process requiring patience and skill. It is usually done by men, who as boys learn the skill at an early age and with experience can produce perfectly registered designs without the use of drawn guide lines. There are several variables in applying the perfect amount of wax to achieve clarity and precision in the waxed design. The recipe of the wax itself is often a guarded secret and the temperature has to be just right, the amount of wax on the cap just enough to avoid blotches or loss of definition, and the speed of the application timed to perfection. The registration is the most difficult part of the work, some designs require the use of a combination of several caps to complete the design.

The cap is a stamp made of copper used to ‘print’ hot wax onto fabric. The cap heats up on a pad in a shallow pan of wax, when the ideal temperature is reached the cap will hold enough wax to print a single time on the cotton. The process continues by replacing the cap into the wax pan and then carefully aligning the next application of the cap on to the fabric to repeat the design.

This task takes great skill, having tried it myself with much difficulty, I really appreciate the ease at which the men appear to race through their metres of cloth, applying perfect wax motifs every time, all faultlessly registered.

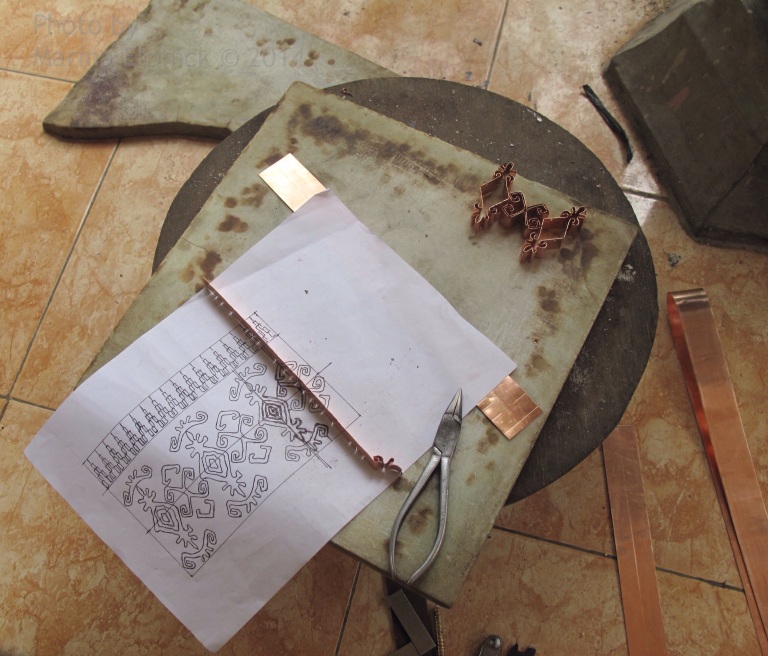

We visited a cap making workshop with Tatang our guide and watched the different stages of the cap being made. Cap-makers are highly skilled in this specialised craft and their caps are works of art in their own right.

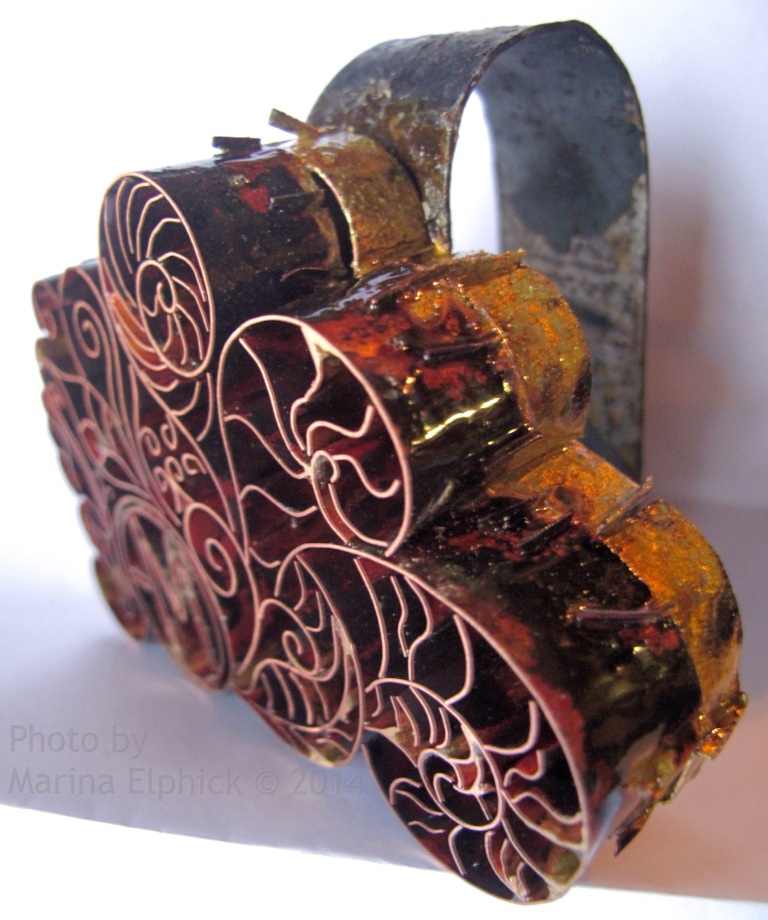

The cap is constructed from hundreds of small pieces of copper, carefully bent and arranged to create a motif or pattern involving many hours of intricate and fiddly work cutting and fixing the copper shapes into a delicate design, then it is soldered into place.

After soldering, the cap is set in a wax resin which is then left to harden before filing the printing edge of the copper cap. This is the only way to file flat such a soft metal.

The finished cap has been filed. The wax resin will now be removed with heat.

While there I commissioned a cap of my own using a motif design with my signature logo incorporated. After six days my cap was delivered to the hotel, my drawing had been interpreted exactly by Saelan the cap-maker, every little detail and swirl was translated to copper, I was really impressed !

I realised at the last moment that my design would need reversing to a mirror image of itself for the cap print to appear true.

Hi Marina

Again a very informative blog giving us an insight into this skilled craft,

though these repetitive designs lack the intuitive creativeness of free expression by the artists. Thanks for keeping us up to date with your travels and research and we look forward to seeing the outcome of all the new influences on your own work.

LikeLiked by 1 person

Hello Marina! I currently learn about batik as the heritage of my own root, Indonesia.

I am glad that you write the knowledge you got regarding batik and all the processes during your visit to Yogyakarta.

Thanks for your thorough and informative post. Appreciate it much. 🙂

LikeLiked by 1 person

Hi Marina, lovely photos and absolutely love this post! Just wondering if you would be able to share where this place is and the person to contact if I would like to visit? Thank you – Faye

LikeLike

Hi Faye,

The photos were taken in several villages around Yogyakarta including Tembi where I met Tatang. I think it is best if you email me for more info. Thanks for your comment, Marina

LikeLike

How did you commision your tjap? Would love to get one or two

LikeLike

Hi Bridget,

I commissioned my tyap while I was staying in Tembi, outside Yogyakarta. My friend Tatang arranged a meeting with Saelan and took me to his workshop which was in a remote location about 16 miles outside Yogyakarta. Saelan creates tjaps (caps) for local craftsmen and women, I am not sure if they do mail order overseas. All I can suggest is that you contact Tatang Elmy Wibowo on this email

leksaganesha@gmail.com

Best wishes,

Marina

LikeLike